R&D 소개

- 모바일에서 모빌리티까지, AI 시대의 핵심을 연결하는 “BH Group”

Technology Roadmap

Technology Roadmap

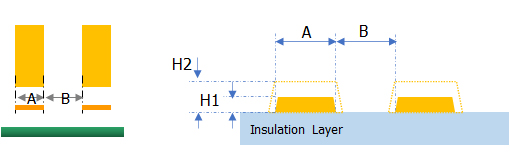

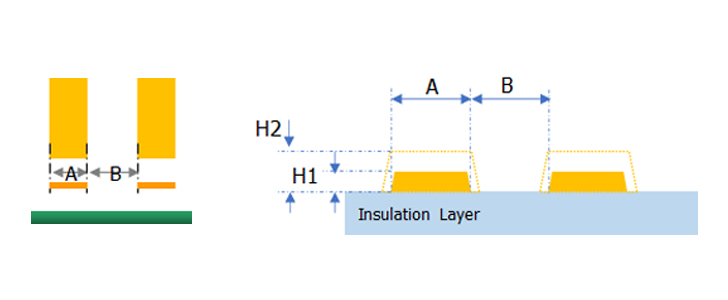

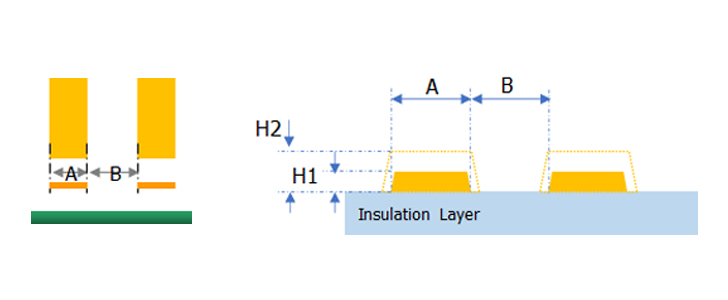

Pattern Technology

- A / B : Line / space (um)

- H 1 : Base Copper Thickness (um)

- H 2 : Base Copper + Cu Plating Thickness (um)

| Pattern Pitch ( Line/ Space ) |

Cu Thickness | Double side | Multi & Rigid Flex | |

|---|---|---|---|---|

| No Plating ( No Via ) | Cu Thickness & Pattern width | |||

| Method | Cu Thickness | 21um | ||

| 9㎛ | 12㎛ | |||

| 2023 | Etching | 25/30 | 30/30 | 40/50 |

| 2024 | Etching | 20/25 | 25/30 | 40/50 |

| mSAP | - | 25/25 | 35/35 | |

| 2025 | Etching | 20/25 | 20/30 | 35/45 |

| mSAP | - | 20/20 | 25/30 | |

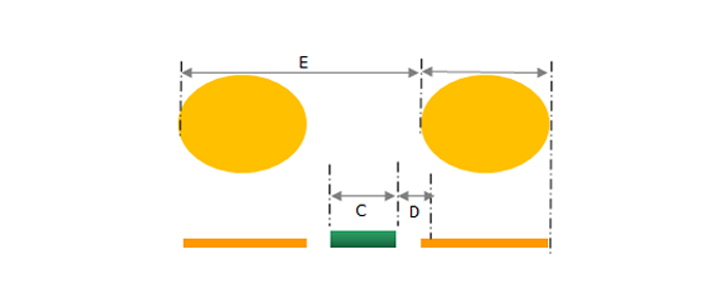

Via Hole Technology

- C : PSR ink dam

- D : Metal & PSR dam Space

- E : BGA pitch

- E’ : BGA pad Size ( um )

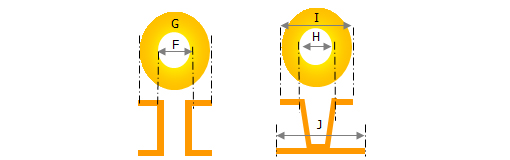

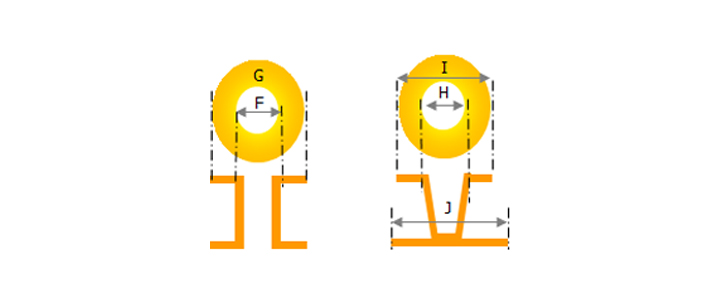

- F : Mechanical drill hole

- G : Mechanical drill pad (Outer land / Inner land)

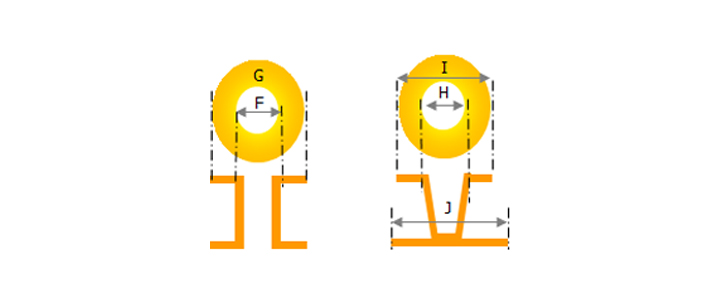

- H : Micro via hole ( um )

- I : Micro via target pad ( um )

- J : Micro via capture pad ( um )

| Via Hole & PAD ( Via Size / PAD Size) |

2023 | 2024 | 2025 | ||

|---|---|---|---|---|---|

| Double side (Cu/PI/Cu=12/20/12) |

Laser Drill | Blind Hole | 100/250 | 75/235 | 70/220 |

| Through Hole | 75/250 | 50/220 | 35/200 | ||

| Mechanical Drill | Through Hole | 100/280 | 90/260 | 80/250 | |

| Multi & RF | Laser Drill | Blind Hole | 100/250 | 90/240 | 85/240 |

| Mechanical Drill | Through Hole | 100/280 | 90/270 | 90/250 | |

자재에 대한 기술력

Unit :mm| Time Frame | 2023 | 2024 | 2025 | Note | |||

|---|---|---|---|---|---|---|---|

| D e s i g n |

BGA Ball Pitch | 0.50 | 0.45 | 0.40 | |||

| Tolerance | Pattern & Via Annual Ring | ±0.075 | ±0.070 | ±0.060 | Double Side | ||

| Solder mask Resist | Solder mask Resist | ±0.040 | ±0.030 | ±0.020 | |||

| Dielectric Thickness | PI Film | Polyimide | 0.0075 | 0.0075 | 0.0050 | Minimum | |

| Adhesive | 0.015 | 0.013 | 0.01 | Minimum | |||

| Adhesive | Bonding Sheet | 0.015 | 0.01 | 0.01 | Minimum | ||

| Prepreg | 0.04 | 0.035 | 0.030 | ||||

| M a t e r i a l s |

RF Stack up ( Rigid / Flex ↓) | 12L / 4L↓ | 14L / 2L↓ | 16L / 2L↓ | |||

| Low Dk (PI / PrePreg / Bonding) | 3.2/3.7/2.7 | 3.6/ 2.9/2.35 | ← | ||||

| Low Df (PI / PrePreg / Bonding) | 0.005/0.017/0.0159 | 0.0025/0.0025/0.0026 | ← | ||||